FMEA (Failure Mode and Effects Analysis) is a structured, analytical method for the early identification of potential errors, risks, and weaknesses. The aim is to evaluate these systematically and derive effective measures for prevention. Today, the method is an integral part of process development and, especially in complex processes, supports the safeguarding of internal company expertise and the utilization of synergy effects in similar products and processes.

Based on the harmonized reference manual of the AIAG (Automotive Industry Action Group) and the VDA (German Association of the Automotive Industry), this seminar provides the necessary fundamentals and decision-making aids for the targeted application of FMEA in your company.

The aim of this seminar is to teach participants how to use FMEA (Failure Mode and Effects Analysis) as a tool for actively preventing errors before they occur. Participants will learn how FMEA can be used as a cross-team tool to improve the quality of products and services in the long term.

The seminar or workshop offers a comprehensive overview of the possible applications of process FMEA and its integration into existing quality strategies. A central component is the practical teaching of the VDA-compliant application of the 7 FMEA steps, which have become established across all industries.

In addition to the new approach, the introduction and handling of task priority (AP) is also discussed, which is increasingly replacing the classic risk priority number (RPN).

Seminar Content

- Development of FMEA and its fundamentals

- Procedure for creating the FMEA

- Process FMEA according to the VDA/AIAG method (7 steps of FMEA)

- Application and implementation of PFMEA in practice

- Identification and consistent treatment of “special characteristics” in the PFMEA

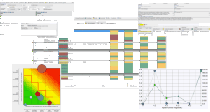

- Risk assessment using task priorities (AP) and risk matrices

- Linking product and process FMEA

- Linking process FMEA and production control plans (PCP)

- A total of 7 workshops will be held during the seminar.

The results of the workshops are provided as PDF and Excel files for further practice and use.

Six moderated group work sessions systematically teach participants how to identify and assess potential risks and define targeted measures for improvement. The practical implementation of the necessary FMEA steps for creating process FMEA in small groups helps participants to consolidate the knowledge they have learned and apply it directly in practice.

| Inquiry | |

| Individual coaching | Dates |

Additional Information

This training course is aimed at employees and managers from manufacturing industries who work in quality assurance, quality management, and product and process development. It is particularly suitable for quality representatives (QR), quality managers (QM), process managers, development engineers, and quality planners who want to learn the FMEA method and apply it systematically.

The seminar lasts 2 days, 8:30 a.m. – approx. 5:00 p.m. (on-site / online)

Seminar date by arrangement.

The number of participants is limited to a maximum of 12 people. If possible, please bring a laptop to the seminar so that you can perform the practical exercises optimally.

All participants will receive comprehensive training materials from GUKSA GmbH as well as a certificate of attendance upon completion of the seminar.

As part of the seminar, practical application software based on Excel will be provided free of charge. This allows participants to work directly on all case studies and workshops on their own laptops—the results can then be further utilized within the company.

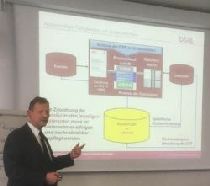

The organizer provides all necessary materials, including a seminar room, flipchart, projector, beamer, pinboards, and other equipment. Application examples are also provided to ensure practical relevance.

Price for training per participant: flat rate of €990

plus statutory value added tax.

Invoices will be issued after the seminar has taken place and are to be paid within 30 days net.

We would be glad to provide you with a customized quote for in-house training courses.

Contact us by email, using the contact form, or by phone—together we will discuss your desired topics, practical examples, and specific requirements in order to tailor the seminar precisely to your company.

We look forward to receiving your inquiry!

Certified 1st/2nd party auditors IATF 16949 (VDA QMC), process auditors VDA 6.3 (VDA QMC), ICO ISMS 27001 PROFESSIONAL / ICO ISMS Auditor ISO/IEC 27001, risk manager according to ISO 31000 / ONR 49001 with many years of experience in establishing and implementing process FMEA in the organization.

Trainer for product, process, and FMEA facilitators, as well as examiner at the DGQ.